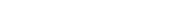

Neova Technologies Inc, part of Bioseutica Group, produces several grades of Trypsin, with properties that endow each with particular advantages. In this post, we outline the key differences between our trypsin grades and the applications for which they are best suited.

Trypsin SE

Neova Technologies Inc. extracts pancreatic enzymes from government certified porcine sources using multiple processing methods. One of these yields Trypsin SE (pancreatin), which has found effective use in applications including whey protein hydrolysis, and in the production of hypoallergenic infant formulae. This is also used in formulations of dietary supplements, and in diabetes and ophthalmic research. More detail about Trypsin SE (pancreatin) and its applications can be found in our previous blog post.

Trypsin VI

Another of our production methods yields Trypsin VI, an enzymatic mix comprising both trypsin and chymotrypsin. Trypsin VI has found effective use in the food, feed, and pharma industries, and as with all grades of our Trypsin, Trypsin VI can be used to improve the digestibility of infant formula, as well as rendering such formulae hypoallergenic. It is also used as an excellent source of the two main enzymes, trypsin and chymotrypsin in dietary supplements and functional foods to reduce muscle inflammation and subcutaneous oedema and bruises.

Trypsin II

An alternative to Trypsin VI is Trypsin II, which through our in-house processing methods has significantly reduced chymotrypsin activity. This is of particular interest to the food industry, as chymotrypsin can cause off-taste, as a result of its hydrolysis of aromatic amino acids which contribute to food flavour profiles. Trypsin II can thus be applied to prevent what could otherwise impart negative organoleptic impacts in food processing. This also makes it well suited to food applications including improving digestibility, reducing allergenicity (particularly milk-derived casein and whey), meat tenderisation, whey protein hydrolysis, and for the improvement of whip and taste. Trypsin II is also highly valued in vaccine production, and for cell culture applications, where chymotrypsin activity is not necessarily desired, nor required.

Trypsin IV and Trypsin 1:250

Neova Technologies Inc. also offers low-endotoxin trypsin preparations, Trypsin IV and Trypsin 1:250. These are highly valued for cell and tissue culture applications including vaccine development. For these purposes, in particular, the use of highly standardised, low endotoxin reagents is of key importance for not only their reliability, but also the optimisation of yield, and reproducibility. Trypsin 1:250 and Trypsin IV are both low-endotoxin powder products, standardised to customers’ desired target protease or trypsin activities. These products are also available as irradiated or non-irradiated powder blends for direct use in tissue culture media.

Trypsin I

Our highest purity, most concentrated trypsin preparation is Trypsin I, which meets the requirements of both the United States Pharmacopoeia (USP), and the European Pharmacopoeia (EP). Trypsin I finds use as a reference standard in protein analytical (MS) techniques, and in cell and tissue culture where adherence to USP or EP guidelines is required. Trypsin I can also be used in the production of less concentrated, standardised trypsins as required for your particular application.

We hope that this has helped to clarify the key differences in our extensive range of trypsin products. To learn more, request a specific formulation, a sample, or to make an order don’t hesitate to get in touch.

Our Grades of Trypsin, and their applications

Click on the products below to discover more about each of our Trypsin grades:

Medical, Pharmaceutical, and Research

| Application Suitability | TRYPSIN VI | TRYPSIN IV | TRYPSIN II | TRYPSIN I | TRYPSIN 1:250 | TRYPSIN SE Pancreatin |

|---|---|---|---|---|---|---|

| Vaccine Production | ||||||

| Cell and Tissue Culture | ||||||

| Mass Spectroscopy | ||||||

| Diabetes & Ophthalmic research | ||||||

| USP / EP guideline conformance | ||||||

| Reduce Oedema and Bruising | ||||||

| Enteral Feeding |

Food Processing, Infant Formula & Dietary Supplements

| Application Suitability | TRYPSIN VI | TRYPSIN IV | TRYPSIN II | TRYPSIN I | TRYPSIN 1:250 | TRYPSIN SE Pancreatin |

|---|---|---|---|---|---|---|

| Whey Protein Hydrolysis | ||||||

| Production of Infant Formula | ||||||

| Production of Hypoallergenic Infant Formula | ||||||

| Food Processing | ||||||

| Meat and Seafood Tenderisation | ||||||

| Enhancement of Food Digestibility | ||||||

| Dietary Supplementation | ||||||

| Functional Foods |

USP specifications per Trypsin grade

Please note: This table outlines our experience of the optimal applications per NTI Trypsin grade. This information is not exhaustive of all possible applications, but a starting point from which to select a grade for your use case.

| Specification | TRYPSIN VI | TRYPSIN IV | TRYPSIN II | TRYPSIN I | TRYPSIN 1:250 | TRYPSIN SE Pancreatin |

|---|---|---|---|---|---|---|

| Trypsin U/mg USP | ≥ 2500 | ≥ 250 | ≥ 450 | >2500 | ≥ 250 | / / / |

| Chymotrypsin U/mg USP | ≥ 250 | ≤ 75 | ≤ 75 | ≤ 50 | ≥ 75 | / / / |

| Endotoxin EU/mg | / / / | ≤ 10 | ≤ 10 | / / / | ≤ 10 | / / / |

| Protease U/mg USP | / / / | / / / | / / / | / / / | > 220 | > 250 |

Optimal Application Suitability Reference Table: This table outlines our experience of the optimal application per Neova Technologies Inc. Trypsin grade. Note that this table is neither exhaustive of the specific applications, but a starting point from which to select a grade for your application. Please read below for detailed applications per grade and contact us with any application or grade-specific queries.

No Warranty: The information contained herein is provided in good faith and, to the best of our knowledge, is true and correct. However, no warranty or guarantee is implied or inferred and the information may be subject to change without prior notice. Neova Technologies Inc.’s products are sold with the understanding that the purchaser will conduct tests to determine the suitability of these products for their particular use.